New Generation fast ,Compact‚ user friendly, Reliable & Low Cost‚ that´s what Fuji Electric´s new PXF series controllers are all about. The PXF series‚ the newest member of the Fuji controller family‚ features a Waterproof front structure‚ Short Depth & Largest Bright colour LCD display size. Abundance of features packed in the PXF makes it the most preferred controller in the Process Industry. Apart from the standard Auto–tuning & Fuzzy Control‚ the PXF also carries a Self–tuning mode, Universal Input and Motorised value coltrol‚ whereby the controller learns the process behavior and optimizes the control action.

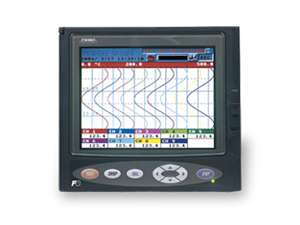

The compact PHR Paperless Recorder displays up to 27 channels of data on a brilliant 5.7" TFT color LCD. A wide variety of display modes allow users to view data as trends (horizontally or vertically)‚ bar graphs‚ analog meters‚ digital / numeric output‚ totalized output‚ event summaries‚ and more.

Switch between display modes quickly and easily with the 8–key front panel. The adjustable–time screen–saver function extends the life of the display and reduces power consumption.

Provides expandable capability at reduced cost per loop.

Fuji PUM series is a "back of panel" controller. The units are designed to operate on their own‚ or in conjunction with a large range of PLC´s‚ HMI´s and SCADA systems. Configuration is carried out via a PC link. Specific applications can be pre programmed by our engineers prior to dispatch.

When they are used on their own‚ the PUM range of modules can handle single or multi loop control applications and provide PLC‚ alarm or communication functions. Alternatively when they are used with a PLC‚ time consuming operations such as fast response multi loop control can be delegated to the PUM‚ allowing your PLC to focus on supervisory or safety critical operations.